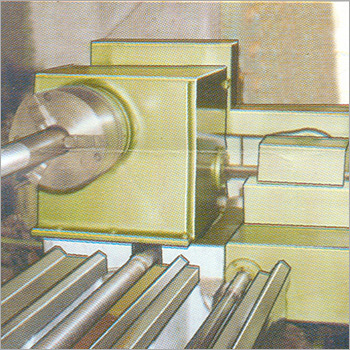

Spline Hobbing Machines

Product Details:

- Product Type Gear Hobbing Machines

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Warranty 12 Months

- Usage & Applications For Industrial Use

Spline Hobbing Machines Price And Quantity

- 1 Unit

- 250000.00 - 300000.00 INR/Unit

Spline Hobbing Machines Product Specifications

- For Industrial Use

- Automatic

- Electricity

- Painted

- 12 Months

- Gear Hobbing Machines

Spline Hobbing Machines Trade Information

- 1 Unit Per Week

- 1-6 Months

- All India

Product Description

We are a remarkable entity, engaged in offering superior assortment of Precision Gear Hobbing Machines that are highly efficient in conducting the cutting process of spur and helical gears. These machines are manufactured with the aid of pioneering technology and high grade components in adherence with set industry standards. Moreover, our proficient workforce, strictly test these machines,before the final delivery at clients' end, to ensure a defect-free range from us. Offered Precision Gear Hobbing Machines are available in various technical specifications at industry leading prices.

Features:

-

High operational fluency

-

Less power consumption

-

High load bearing capacity

-

Durability

| Capacity | | Module | |||||

| 2MOD | 4MOD | 8MOD | 10MOD | 14MOD | 20MOD | ||

| Maximum Module of Gear Hobbing | Module | 2 | 4 | 8 | 10 | 14 | 20 |

| Steel Gear | Module | 2 | 5 | 8 | 10 | 14 | 20 |

| Cast iron Gear | Module | 2.5 | 5 | 9 | 12 | 16 | 24 |

| Maximum Diameter of Spur Gear Hobbing | MM | 150 | 400 | 700 | 1000 | 1400 | 2000 |

| Maximum Length of Hobbing for Super Gear | MM | 200 | 350 | 400 | 450 | 650 | 950 |

| Minimum OD | MM | 5 | 10 | 50 | 80 | 120 | 180 |

| Maximum OD | mm | 175 | 500 | 750 | 1000 | 1500 | 2200 |

| Table | |||||||

| Diameter of Table Working Suface | MM | 150 | 325 | 500 | 625 | 750 | 900 |

| Diameter of base Holw | MM | 15 | 32 | 50 | 60 | 90 | 125 |

| Diameter of Dividing Worm Wheel | MM | 142 | 260 | 370 | 425 | 575 | 850 |

| Cutter Head | |||||||

| Setting of Cutter Head | -45% Max.45% | | 125 | 200 | 300 | 400 | 400 |

| Maximum Dia of Hob | MM | 60 | 90 | 130 | 170 | 200 | 250 |

| Maximum Axie Trevel of Spindle on Order | MM | 10 | 15 | 25 | 30 | 50 | 60 |

| Speed | |||||||

| Speed Gear Box Attached for low & High Speed | No Gear Module | | 2.25 | 2.25 | 3.50 | 4.00 | 4.00 |

| Drive | |||||||

| Three Phase A.C. Electric Motor | | 1 HP | 2 HP | 3 HP | 5 HP | 7.5 HP | 10 HP |

| Rapid Motor | | NO | 1 HP | 1 HP | 2 HP | 3 HP | 5 HP |

| Cooling Pump | | 0.10 | 0.10 | 0.10 | | | |