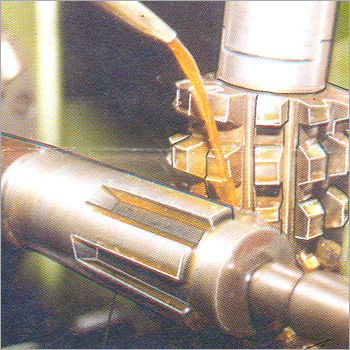

Spline Hobbing Machines

Spline Hobbing Machines Price And Quantity

- 250000.00 - 300000.00 INR/Unit

- 1 Unit

Spline Hobbing Machines Trade Information

- 1 Unit Per Day

- 1-6 Months

- All India

Product Description

We are a noteworthy organization in the domain, engaged in providing high quality range of Worm Steel Cutting Machines that are used in various industries for undertaking cutting and hobbing applications. These machines are precisely manufactured by our dextrous engineers using quality approved steel and avant-garde techniques in tandem with set industry standards. Furthermore, we also test, provided machines on defined quality parameters to ensure their proper functioning. The offered Worm Steel Cutting Machines are available in various technical specifications at industry leading prices.

Features:

-

Noiseless operation

-

Robust construction

-

Easy to operate

-

Operates at variable speed

Specifications:

| Capacity | | Module | |||||

| 2MOD | 4MOD | 8MOD | 10MOD | 14MOD | 20MOD | ||

| Maximum Module of Gear Hobbing | Module | 2 | 4 | 8 | 10 | 14 | 20 |

| Steel Gear | Module | 2 | 5 | 8 | 10 | 14 | 20 |

| Cast iron Gear | Module | 2.5 | 5 | 9 | 12 | 16 | 24 |

| Maximum Diameter of Spur Gear Hobbing | MM | 150 | 400 | 700 | 1000 | 1400 | 2000 |

| Maximum Length of Hobbing for Super Gear | MM | 200 | 350 | 400 | 450 | 650 | 950 |

| Minimum OD | MM | 5 | 10 | 50 | 80 | 120 | 180 |

| Maximum OD | mm | 175 | 500 | 750 | 1000 | 1500 | 2200 |

| Table | |||||||

| Diameter of Table Working Suface | MM | 150 | 325 | 500 | 625 | 750 | 900 |

| Diameter of base Holw | MM | 15 | 32 | 50 | 60 | 90 | 125 |

| Diameter of Dividing Worm Wheel | MM | 142 | 260 | 370 | 425 | 575 | 850 |

| Cutter Head | |||||||

| Setting of Cutter Head | -45% Max.45% | | 125 | 200 | 300 | 400 | 400 |

| Maximum Dia of Hob | MM | 60 | 90 | 130 | 170 | 200 | 250 |

| Maximum Axie Trevel of Spindle on Order | MM | 10 | 15 | 25 | 30 | 50 | 60 |

| Speed | |||||||

| Speed Gear Box Attached for low & High Speed | No Gear Module | | 2.25 | 2.25 | 3.50 | 4.00 | 4.00 |

| Drive | |||||||

| Three Phase A.C. Electric Motor | | 1 HP | 2 HP | 3 HP | 5 HP | 7.5 HP | 10 HP |

| Rapid Motor | | NO | 1 HP | 1 HP | 2 HP | 3 HP | 5 HP |

| Cooling Pump | | 0.10 | 0.10 | 0.10 | | | |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+